Specifications

1.CE ISO 9001:2008 & TUVcertified2.4-dehullers design

3.dehulling adjustable and patented product

1.CE ISO 9001:2008 & TUVcertified

2.4-dehullers design

3.dehulling adjustable and patented product

FOXNUT DEHULLING&SEPARATING EQUIPMENT TFQS300

FUNCTIONS AND FEATURES

Foxnut dehulling and separating equipment is our company’s patented product with the independent intellectual property, which is the optimum equipment for foxnut processing among the similar products worldwide currently. Right after precleaned and sized, and one by one the each individual foxnut will go for dehulling, shell-kernel separation, seed-kernel separation and meantime the un-hulled foxnut will go back to dehullers automatically for 2nd round of dehulling.It’s a dry method processing for hulled foxnut. It features higher automation, non-stop processing, higher recovery of hulled foxnut and better effect for removing shells.

COMPONENT

The equipment consists of input hopper, elevator, dehulling and separating unit and electric control cabinet.

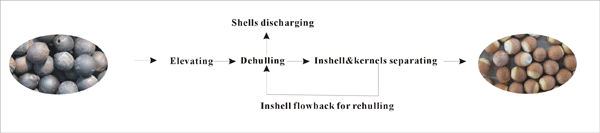

PROCESS

TECHNICAL PARAMETERS

Power | 9.64kw(380v 3phase 50Hz) |

Input capacity | 200-300kgs/hour(varies with raw materials) |

Foxnut fit for dehulling in mm | 6-13mm |

% of dehulled foxnut in halves | 10-15% minimum |

% of brokens | 10-15% adjustable |

Space occupied | 5.5m*3.0m |

Height | 2.8m |

Weight | 5.0mts |