Product Description

Introduction of iron oxide tunnel microwave drying machine :

Compared with conventional microwave equipment:

1)Low temperature:under one atmospheric pressure (101.3 kpa), the boiling point of water is 100 °C.But under 0.073 of one atmospheric pressure(7.37 kpa), the boiling point of water is only 40 °C.It is on negative pressure condition when using microwave vacuum device,material can be processed under low temperature.So the quality of the material can be guaranteed tremendously. The machine is especially suitable for drying material which need to dry in the low temperature, such as herbal extract,ginseng,ect.

2)Pressure:In negative pressure environment with microwave vacuum device,moisture evaporates faster in the lower temperature.

Compared with conventional microwave drying equipment:

1)Penetration:because it is in vacuum situation when using conventional vacuum drying equipment,heat cann't transfer in the form of convection and can only conduct.So the heating speed is slow,drying time is long and the energy consumption is excesive.However,Microwave vacuum drying equipment adopts radiation way to transfere energy and it heat wholly without any medium.Itavoids the above shortcomings.

2)Evenly:microwave heating is in and outside of the material at the same time,the temperature difference is very small in and outside of the material.So it is more evenly when drying materials,and the heating efficiency is greatly increased.

3)Quickly:because of the penetration of the microwave and the radiation way to transfere energy, materials is heated inside and outside at the same time.Thus the drying speed is greatly improvedl.

Scope of application:

The unique mechanism of microwave make the material heated inside and outside at the same time.Vacuum,in other word in a negative pressure,the material can be dried in a low temperature.This makes the material being heated evenly,maintain its originalcolor,and the material composition donât be changed.All in all, microwave vacuum drying equipment effectively guarantees the quality of raw materials.

The main use of microwave drying machine:

1.Suitable for dying materials with high added value and heat-sensitive character,such as agricultural and sideline products,health products,food,medicine,fruit and vegetables,ect.

2.Can be used to dry or take off crystal water of herbal extract,chemicals.

Specification of food extruder:

Note: The above technical parameter should prevail by the product operating manual ,specific parameter will very according to your different customization needs.

Usage: Microwave Vacuum Dryer is used for drying all kinds of herbs, including raw herbs, herb powders, herb pellets, etc

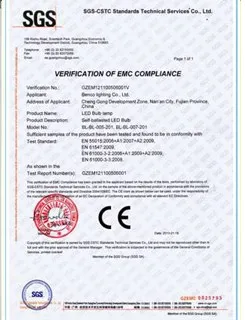

Certifications

Certifications

Detailed Images

Detailed ImagesFeatures of machine parts:

Our Service

Our ServicePre-sale services:

Act as a good advisor and assistant of clients; enable them to get rich and competitive from the returns of their investment.

1) Select suitable equipment model.

2) Design and manufacture products according to clientsâ special requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer

Services during the sale:

Respect clients; devote ourselves to improving the total value of clients.

1)take photos(including raw material, semi-products, final products, and loading products)

2) Pre-check and accept products ahead of delivery.

3) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services:

Provide considerate services to minimize clientsâ worries.

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace) to every customer.

3) Install and debug the equipment, ensure the dryer running smoothly.

4) Examine the equipment regularly.

5) Take initiative to eliminate the troubles rapidly at site.

6) Distribute the guarantee fittings door-to-door.

7) Provide technical exchange and support.

8) Provide maintenance for big items.

9) The most preferential prices to provide customers the quick-wear parts.

Packing & Delivery

Packing & DeliveryPackaging & Shipping:

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finaly pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

Contact To Us:

Mr. (Director of sales department)

Skype:

Mob(whatsapp):+0086

Tel:+0086 531 85927300

Related Products

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate