Product Description

Introduction of Industrial Microwave Drying Machine :

Industrial Microwave Drying Machine for Tea Steaming/ Tea Sterilization is used of electro-magnetic induction or infrared radiation to dry the raw material.By microwave energy permeation, the material inner moisture quickly been heated and gasified, forming a strong outward diffusion situation, to make the moisture extremely quickly spread to the surface.

Industrial Microwave Drying Machine fits for drying and sterilizing powders, granular, sheet-like or gel-like food, andadditive, spices, flavoring, medicine, raw material of herbal medicine, nutritional health products,agricultural & sideline products, non-fired(or oil saving)instant noodles, noodles, rice powderneedles, soy products, preserved meat, dried fish, tea, tobacco, ceramic, construction industry and so on;

The Main components of Industrial Microwave Drying Machine :

1.Microwave generator system

2.Microwave box

3.Temperature controlling system

4.Humidity controlling system

5.Transmission system

6.PLC and touch screen control system

7.Humidity discharging system

8.Electrical cabinets

9.Cooling system

10.Hot air recycling and circulatory system

Specification of food extruder:

Note: The above technical parameter should prevail by the product operating manual ,specific parameter will very according to your different customization needs.

Usage: Microwave Vacuum Dryer is used for drying all kinds of herbs, including raw herbs, herb powders, herb pellets, etc

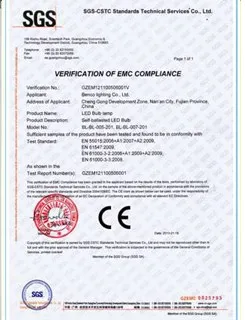

Certifications

Certifications

Detailed Images

Detailed ImagesFeatures of machine parts:

Our Service

Our ServicePre-sale services:

Act as a good advisor and assistant of clients; enable them to get rich and competitive from the returns of their investment.

1) Select suitable equipment model.

2) Design and manufacture products according to clientsâ special requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer

Services during the sale:

Respect clients; devote ourselves to improving the total value of clients.

1)take photos(including raw material, semi-products, final products, and loading products)

2) Pre-check and accept products ahead of delivery.

3) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services:

Provide considerate services to minimize clientsâ worries.

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace) to every customer.

3) Install and debug the equipment, ensure the dryer running smoothly.

4) Examine the equipment regularly.

5) Take initiative to eliminate the troubles rapidly at site.

6) Distribute the guarantee fittings door-to-door.

7) Provide technical exchange and support.

8) Provide maintenance for big items.

9) The most preferential prices to provide customers the quick-wear parts.

Packing & Delivery

Packing & DeliveryPackaging & Shipping:

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finaly pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

Related Products

Related Products

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate