Hydraulic full automtic road brick making machine/ block machine with good quality

Product DescriptionBrief introduction of brick /block machine

The block molding machine is suitable for fixed production of various specifications of the standard brick, hollow block, porous brick and concrete products etc.

QT series block production line mainly includes QFT12-15/9-15 automatic block production line (open type) and QFT12-15/QFT9-15 automatic concrete block machine (closed type). This line composes of four parts including batching and mixing system, block machine and lifting board system, stacking system and fully automatic centralized control system. It can process kinds of raw materials, such as gravel, concrete, industrial residue (fly ash, cinder, slag, gangue, etc.), ceramsite, construction waste, and so on. Our QT series automatic block production lines or automatic concrete block machines can produce blocks, color bricks, garden bricks, porous bricks, etc.

Application

By changing moulds, this concrete block production line can produce curb bricks, river bricks, slope protection bricks, square bricks, driveway bricks, sidewalk bricks, decorated bricks, grass bricks, small wall blocks, etc. It is a multi-purpose automatic concrete block machine that can completely meet different market demands. Products manufactured from this line are also used in roof thermal-protective coating and in parking lot.

Raw materials :

crushed stone ,sand, cement, etc; many type of industrial waste, like, lime, fly ash, slag, coal gangue, gravel, perlite , ect. .

multiple uses,

it can produce all type of standar d building blocks by changing mould.

1,Multi-holes block and hollow block .

2,Ceram site heat preservation block.

3,Composite heat preservation concrete block

Technical parameter

Brick | Sizes | Output/ mould | Output/Shift(8hours) | picture |

Blocks | 390x190x190mm | 3 | 2880-3600 | |

Porous bricks | 240x115x90mm | 10 | 9600-12000 | |

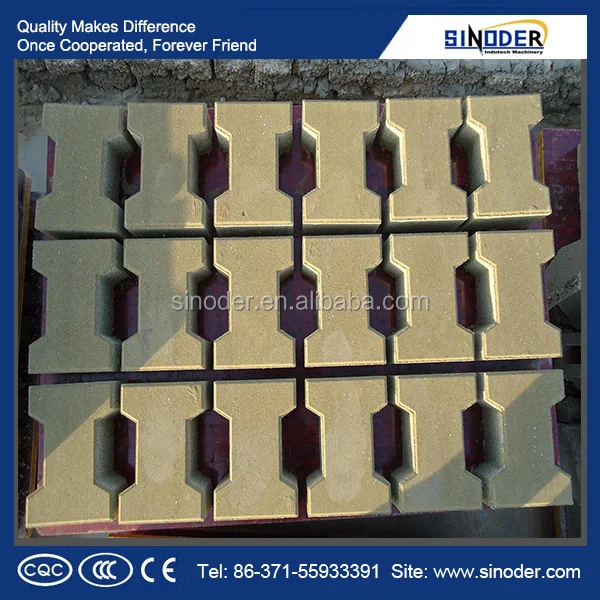

Interlocking block | 200x100x60mm | 12 | 11520-14400 | |

Solid bricks | 240x115x53mm | 20 | 19200-24000 |

Cycle Time | 20-30s/ time | Capacity/8 hours | Paving block 150-200squareHollow block 2400-3000pcs |

Vibration frequency | 4500-5100 Times/sub | Oil pump motor | Y132S2-4 N=5.5kw |

Jack cylinder | 80X300 Φ50 | Side cylinder | 63X250 Φ40 |

Rated pressure of hydraulic system | 8.5Mpa | Total Power | 20.7KW |

Pallet Size | 680 x 535 x 20mm | Gross Weight | About 3000kg |

Machine Dimension | 4000 x 3500 x 2700mm | Load capacity | Standard block 21pcs, Hollow block 3pcs |

Picture of machine

Zhengzhou Sinoder Indutech Machinery Co., ltd (hereafter referred to as "Sinoder") is a joint-stock machinery manufacturing enterprise, integrating industrial scientific research, production and marketing. The company is located in the Industry Area Zone of Zhengzhou, China.

The main products cover industrial drying machines,industrial crushing machines, mineral processing machines, brick machines, biomass energetic machines, environment protection equipment, food oil press machines and other mechanical equipment. Our key product include stone crusher,sand maker, stone washing machine, ball mill, flotation cell, AAC block plant, rotaty drying machines, biomass burner, coal gasifier, oil press machine, packaging machine, breeding machines, fertilizer and pellets machine and other machines.

Sinoder offer not only products with good quality and competitive price, but also top service and solution.

Website: www.sinoder.com

Packaging & Shipping

1.Waterproof packing with the international export standard by 20ft, 40ft, 40hp container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

Our Services

1.Pre-sale services:

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

2.Services provided during the sale:

Respect our clients; present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1) Checking products acceptance ahead of delivery;

2) Introducing the service system to our clients.

3. After-sale services:

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipments;

3) Training the first-line operators on site;

4) Examining the equipment regularly;

5) Taking the initiatives to eliminate the failure(s) rapidly at site;

6) Distributing the guarantee fittings door-to-door;

7) Providing technical exchanging;

8) Providing maintenance for big item

FAQ

If you want to know more information , Pls to contact us

Tel: 0371 55933391 Fax: 0371 55919082